Manufacturing Division

The Manufacturing Division of Time Trax specializes in the production of Expanded Polystyrene (EPS) products for industrial, commercial, packaging, construction, and custom engineering applications.

With a dedicated workforce of 70–80 skilled employees and a complete in-house production line, we offer tailored EPS solutions manufactured to precise densities and client specifications.

Our facility operates as a fully integrated unit — from raw material expansion to moulding, cutting, shaping, and final finishing.

Products We Manufacture

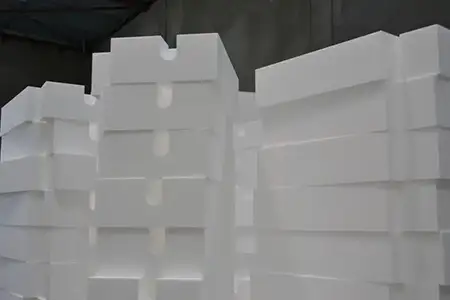

EPS Blocks

Large-format blocks for construction, insulation, packaging, and custom machining.

EPS Sheets

Available in a wide range of thicknesses and densities for insulation, cold chain, construction, signage, packaging, and industrial use.

Custom Profiles

Complex shapes and profiles made as per customer drawings or samples. Perfect for packaging, insulation channels, industrial linings, and technical applications.

EPS Tubes & Pipes

Produced in multiple diameters and densities for packaging, insulation, and protective applications.

Moulded Shapes (As Per Drawings)

Large-format blocks for construction, insulation, packaging, and custom machining.

Production Capabilities

Time Trax has a modern EPS production facility equipped with the following

Pre-Expander & Batch Expanders

Block Moulding Machines

Shape Moulding Press

Cutting & Profiling Machines

• Cutting Machines

• Hot-wire Cutters

• Automatic Sheet Cutters

• Profile-forming Systems

In-House Die & Mould Fabrication

• Faster turnaround

• Lower custom development cost

• Complete design flexibility

• High precision in final shapes

Raw Material & Densities

-

Structural Strength

-

Packaging Needs

-

Thermal Insulation Requirements

-

Weight Considerations

-

Customer Specifications

Applications

-

Packaging (industrial, commercial, fragile goods)

-

Construction & Insulation

-

HVAC Ducts & Insulation

-

Industrial Forming & Lining

-

Cold chain & temperature-controlled logistics

-

Decorative, signage, and architectural applications

-

Engineering mockups & prototypes

-

Automotive packaging & cushioning

Why Choose Time Trax EPS Products